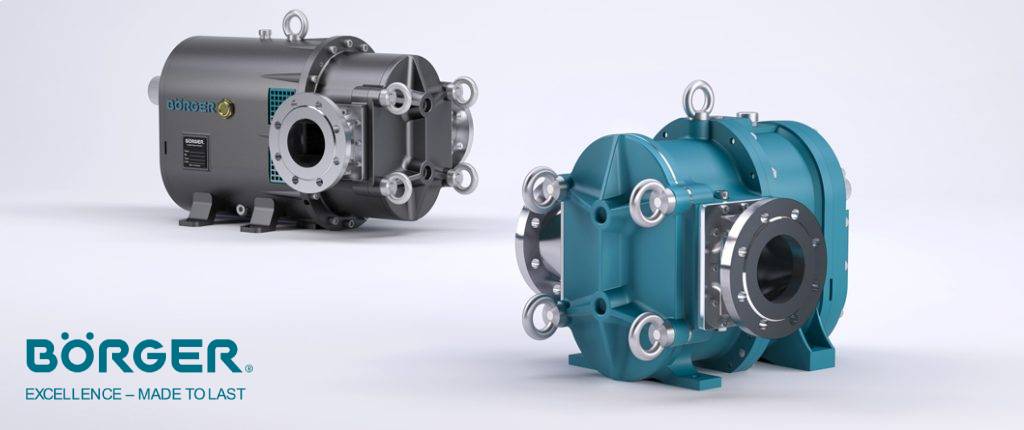

Borger rotary lobe pump series BLUEline and ONIXline in 25 pump sizes (flow rates of 1 to 1,440m3/h).

Product Description

Borger is synonymous for Rotary Lobe Pumps. The simple and ingenious principle of a self-priming, valveless positive displacement pump has found its market in all industries. 17 pump models in five series with flow rates between 0.5 to 1,250 m³/h build the base for your individual pump application.

The variety of components and materials of construction enables Borger to supply an optimized pump for each customer. Rotor shapes and/or tips, elastomer coatings, shaft seals, wear protection plates, and casing materials of each pump are all chosen depending on the pumped fluid.

Borger Pumps feature heavy-duty construction in a compact, lightweight package suitable for mobile applications. Borger’s MIP Design is a unique advantage: MIP (Maintenance-In-Place) allows the quick and convenient replacement of all fluid-wetted parts without the removal of pipes, drives, or other components of the pump unit by your own staff.

Rotors with individually replaceable rotor tips or re-adjustable lobes reduce repair costs, especially with abrasive fluids.

Design Advantages

- Quick Release Cover – allows quick access to all fluid-wetted parts

- Rotors – Patented solutions with fast interchangeable rotor tips, fully coated rotors or re-adjustable lobes, or screw shape design for pulsation-free operation.

- Shaft Seal – Robust and durable mechanical seals as standard, optional with multi seal

- Intermediate Chamber – Located between the synchronizing gear and the pump casing is filled with quench fluid. This fluid prevents any dry running of the mechanical seals and indicates possible seal leakage. It also allows the pump to run dry without damage.

- Rotor Material – coated with a choice of elastomer, PTFE, or stainless steel

- Reversible Flows – Flow can be reversed by rotation direction change, suitable for loading and unloading applications

- Low Shear Operation – Large volume geometry and short suction/discharge distance enable gentle pumping operation.

- Compact Design – High flows on the most limited space

- Pump Casing Protection – Liners made of hardened steel or stainless steel

Products Specifications & Applications

Specifications:

- Flowrate : 1,440 m³/h

- Differential Pressure : 16 bars

- Temperature : 150°C

- Liquid End Materials : Cast or ductile iron, SS316, Buna N, Viton, EPDM or PTFE

Applications:

- Wastewater, sludge and biosolids

- Chemical industry

- Oil industry

- Building industry

- Ceramic industry

- Fish & meat processing

- Paint & coatings

- Starch production

- Sugar industry

- Latex

- Pulp & paper

- Soap, grease, and oil mills

- Fruit and vegetable processing

- Mining industry

- Marine

Please contact us for the latest brochure.

Tell us your needs and we’d love to work

with you.