Product Description

MPUMPS is an Italian-based company that specializes in the design and manufacturing of Magnetic-Driven (Sealless) centrifugal pumps for a variety of industrial applications. With over 40 years of experience in the field, MPUMPS has established a reputation for quality, reliability, and innovation.

The company’s product line includes both horizontal and vertical centrifugal pumps, which are available in a range of sizes and materials to suit various operating conditions. The pumps can handle a wide range of fluids, including clean or dirty water, chemicals, acids, and slurries.

One of the key features of MPUMPS’ centrifugal pumps is their energy efficiency. The pumps are designed to minimize energy consumption, which can help to reduce operating costs and improve overall sustainability. Additionally, the pumps are easy to maintain, with simple designs and easy access to components for quick and efficient servicing.

MPUMPS’ centrifugal pumps have been used in a wide range of industries, including agriculture, food and beverage, mining, oil and gas, and wastewater treatment. The company has a strong commitment to customer satisfaction, with a focus on providing personalized support and tailored solutions to meet each client’s unique needs.

As a distributor of MPUMPS in Malaysia, we are proud to offer our customers a wide range of pump types, including Magnetic-Driven (Sealless) centrifugal pumps, regenerative turbine pumps, side channel pumps, and volumetric pumps.

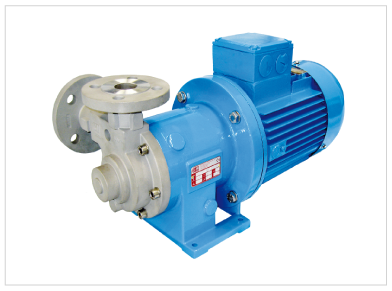

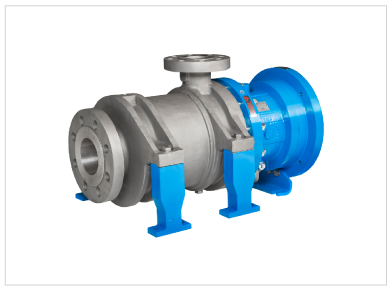

Centrifugal Pumps

Centrifugal pumps are a versatile and essential component in various industrial applications, and MPUMP offers a wide range of centrifugal pumps designed for handling different fluids, including clean or dirty water, chemicals, acids, and slurries. These pumps come in various sizes and materials, ensuring that they meet specific customer requirements for transferring, unloading, or circulating fluids.

One of the primary benefits of MPUMP’s centrifugal pumps is their efficiency, providing a long life with low-cost maintenance. They meet various international standards, including ISO, DIN, ANSI, and API, ensuring they meet the highest quality and safety standards in the industry. These pumps are available in both magnetic drive (sealless) and traditional mechanical seal configurations, providing customers with the flexibility to choose the right pump for their specific application.

MPUMP’s Centrifugal pumps are widely used in several industries, including chemical processing, water treatment, food and beverage, and HVAC. These pumps are ideal for applications where a continuous flow of fluids is required, making them a reliable and efficient choice. They are also suitable for handling fluids with high viscosity, suspended solids, or abrasive particles, making them a versatile pumping solution.

Operating Range:

- Max Flow rates: 4000 m3/h

- Max Head: 2200 m

- Max System pressure from vacuum: 1500 bar

- Temperature range: -150°C to +400°C

- No heat exchanger required up to +350°C

Regenerative Turbine Pumps

Regenerative Turbine Pumps (RTP) uses a series of rotating impellers to generate high pressure and flow rates, making them ideal for applications where high-pressure pumping is required. They are designed for low to medium-flow applications that require high-pressure pumping, providing a smooth and consistent flow that is crucial for precision applications.

MPUMP’s RTPs offer several benefits, including their high efficiency, cost-effectiveness, and pulsation-free operation. They are highly efficient and capable of handling high-pressure requirements with ease, making them a cost-effective solution for a wide range of industries. RTPs also provide a smooth and consistent flow of fluids, reducing the risk of damage to sensitive fluids or equipment. Their durability, reliability, and ease of maintenance ensure long-lasting performance, reducing the risk of downtime and increasing productivity.

MPUMP’s Regenerative Turbine Pumps are widely used in various industries, including chemical processing, water treatment, HVAC, and oil and gas. RTPs are commonly used in applications that require high-pressure pumpings, such as cooling towers, boiler feed, and heat exchangers. They are also used in precision applications, such as medical equipment and fuel cells, where their pulsation-free operation and compact size are crucial.

Operating Range:

- Max Flow: 24 m3/h

- Max Head: 800 m

- Max System pressure from vacuum: 1500 bar

- Temperature range: from -150°C to +400°C

- No heat exchanger is required up to +350°C

Side Channel Pumps

Side channel pumps use an impeller with a series of channels on the side to generate high pressure and flow rates. These pumps are often used in applications where the fluid being pumped contains gas, vapor, or suspended solids, such as in the chemical and pharmaceutical industries.

316 stainless steel (or better) multi-stage barrel construction. Ideal to pump liquefied gasses

and liquids under vapor pressure like condensate, refrigerant, boiler feed water, or LPG (up to

50% gas content).

Volumetric Pumps

Volumetric pumps move fluid by trapping a fixed amount of fluid and then forcing it through the pump. MPUMPS offers a range of volumetric pumps, including diaphragm pumps, peristaltic pumps, and rotary pumps. Volumetric pumps are often used in applications where precise dosing or metering is required, such as in the food and beverage, pharmaceutical, and chemical industries.

- Flow rates up to 3000 l/h, discharge pressure up to 48 bar g.

- Suitable for viscosities from 1 to 1000 cP

- Pulsation free dosing/sampling/transfer pumps

- Flow rates up to 80 m3/h, discharge pressure up to 30 bar g.

- Suitable for lubricating media up to 25000 cP

- Temperature up to +200°C

- Flow rates up to 38 m3/h, discharge pressure up to 5 bar g

- Viscosities up to 10000 cP

Please contact us for the latest brochure.

Tell us your needs and we’d love to work

with you.